Cold Storage Supply Chain

From storage to transportation, moving temperature-sensitive products presents various challenges. Even the slightest changes in temperature can ruin your delicate products. Discover ways to avoid disaster in cold storage management.

How to avoid disaster in your Cold Storage Supply Chain Management?

Here are the areas to improve the cold storage supply chain

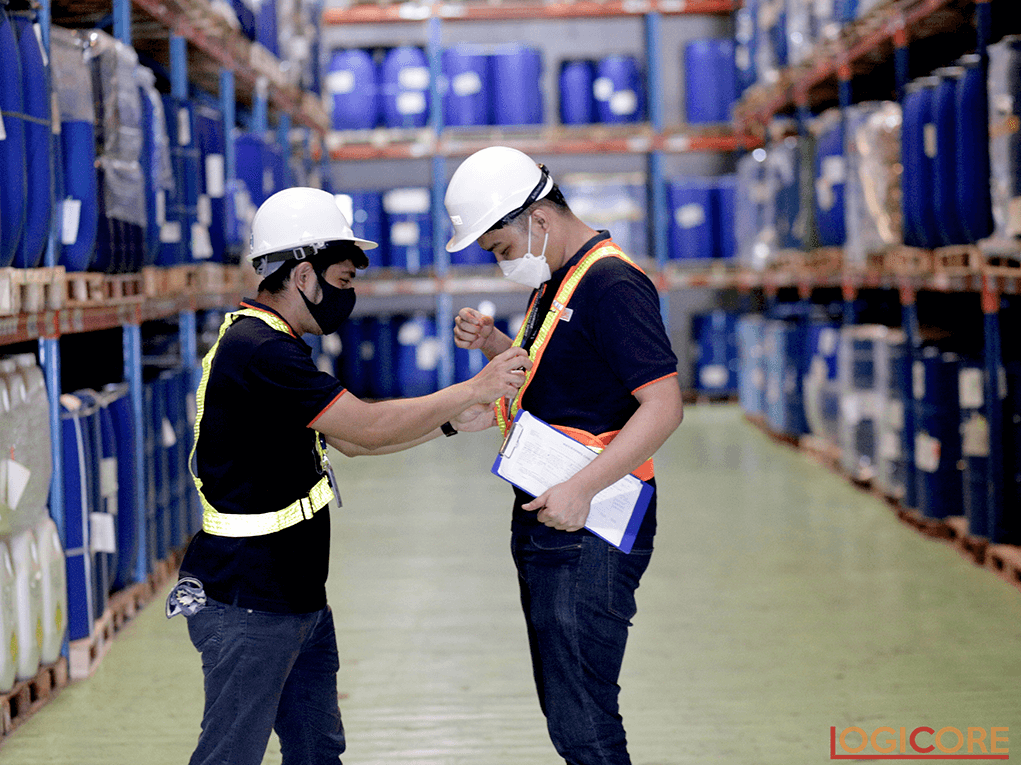

LogiCore has the facilities, team, and technology to optimize your order fulfillment process. Our cold storage warehouse facility is designed to accommodate multiple storage temperature settings. For more information about Us. Read More.

You may also explore 2 Best Practices of Cold Storage Management and the Trends for Cold Storage Facility

BOOK PALLET SPACE NOW!