It is tough for various industries to deliver and supply products in good hands to meet consumer needs. As consumer demand rapidly grows and preferences shift, commodities increase, specifically perishable goods. That’s why supply chain managers have expanded their function to meet the consumer’s demand by way of providing a secure place for temperature-sensitive goods and maximizing the benefits of cold storage. Supply chain managers recognize the ultimate solution to such problems: building more cold storage facilities.

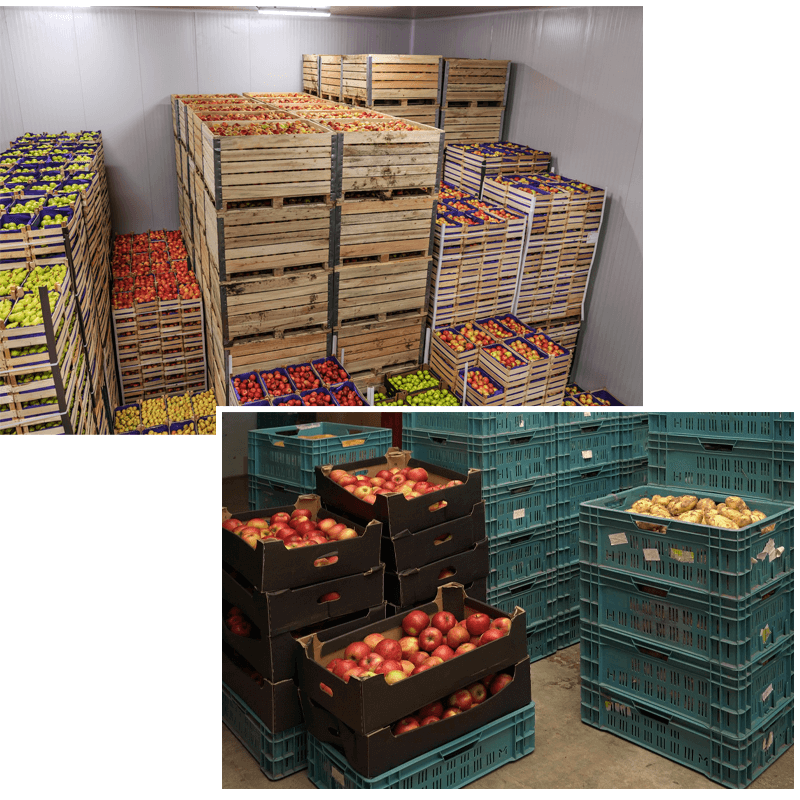

Businesses and consumers find cold storage warehouses necessary as they provide temperature control and allow commodities to remain fresh. The cold storage facility serves as a place where perishable goods can be kept over a period of time. It is an intermediary location before distribution and/or shipment to a distant market.

Cold Storage in Logistics

Cold storage is a logistics method that involves refrigeration techniques to provide customers and clients with a usable condition for temperature-sensitive products. Its primary task is to store temperature-sensitive products appropriately. Various industries rely on this kind of facility as it maintains the quality and integrity of their products. Most sectors, particularly food and beverages, chemical products, and pharmaceuticals, make extensive use of it. Besides its function to preserve and ensure the temperature stability of perishable goods, here are some benefits of a cold storage facility:

Five (5) Main Benefits of Cold Storage

1. Prolonging Shelf-Life of Perishable Goods

Cold storage is a logistics facility where perishable goods are stored at lower temperatures than average and done in several ways. The controlled atmosphere storage or refrigerated warehouse regulates various gases through precision devices and instruments to keep raw products as fresh as possible. Reducing room temperature or lowering oxygen levels helps the respiration of goods and increases its carbon dioxide supply.

2. Temperature Control

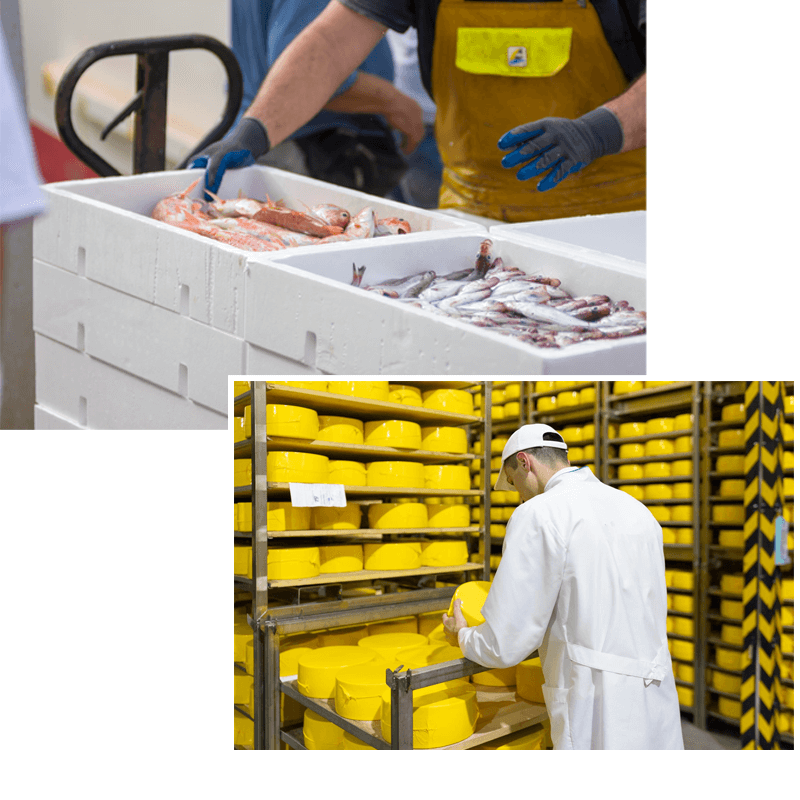

There is no such thing as a one-temperature-fits-all, especially when it comes to sustaining and ensuring the safety of perishable products. Some industries use a temperature standard that will accommodate the majority of their products. The most common temperature standards are:

-25 to -30 °C:

This can be maintained by conventional refrigerated units that are mostly used for transporting seafood and ice cream.

-10 to -20 °C:

This temperature range falls into the range of uses for transporting different kinds of frozen meat and frozen bakery products, such as cakes and bread.

2 to 4 °C:

It is commonly used to transport fruits, vegetables, and fresh meats as it bestows optimal shelf life without freeze damage.

2 to 8 °C:

This range comprises most of the pharmaceutical goods, such as vaccines, that are being transported and are mostly transported in smaller refrigerated packages.

12 to 14 °C:

It is called “banana” as it is mostly utilized by tropical fruits such as bananas, oranges, and pineapple, as do tubers, such as potatoes, in the vegetable sector.

3. Cost-Efficiency

Many businesses prioritize their products’ sustainability, quality, and safety. Because of this, their primary concern is how they will save a lot of money but at the same time offer valuable products. As cold storage prevents deterioration, it might lessen the company’s loss, resources, and energy wasted by clients. For instance, the recent development in cold storage technology—gas-controlled storage—keeps the room pressure as low as 0.8 °C, which saves a lot of energy and saving a lot of energy will lessen the client’s expenses.

4. Carefree Transportation

Industries that need their products, such as frozen foodstuffs, poultry, dairy products, and even pharmaceutical products, to be transported from their storage facility cannot be distributed at ordinary temperatures. A sudden and slight temperature change can cause contamination and unmarketable goods. It is a huge advantage for them to have a portable cold storage unit, as it is used to keep and transport their products safely at low temperatures. It can also be used to transport highly reactive chemicals that would be impossible to transport.

5. Saves Space

Space utilization becomes a pressing matter for businesses with too many products to store, and it becomes an even bigger issue for those with temperature-sensitive goods. In this case, you have another space to conveniently store your excess and raw products, which will be easy to find whenever you need them. You will not just keep your place organized, but you will also reduce waste and store your products category-wise.

Are you searching for a logistics company that offers cold storage rooms for your business? Pick the perfect one; choose Logicore, Inc. We will provide you with a space to keep your products safe and offer you a cold storage room, regardless of the size you need!

Reach out to us by sending in your requirements.